Description of the FoamFatale™ system

A method has been developed which eliminates the limitations of conventional systems.

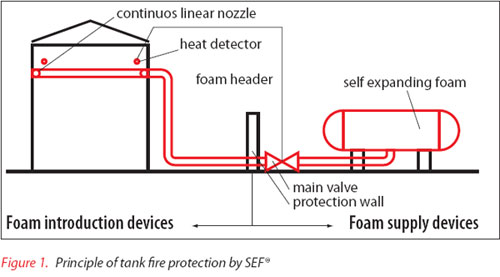

The concept of this new system is that perfectly prepared foam is stored under pressure in a vessel. On release of the foam from the vessel, expanded foam is formed at the location where the expansion takes place.

The patented system is called "Self-Expanding Foam" system, abbreviated as SEF®.

Preparation of foam

- Self-Expanding Foam is prepared well in advance under calm and controlled conditions.

- The probability of an off-spec composition of the foam is eliminated.

- The pre-mixed foam is stored in a pressure vessel until the moment of use.

- The foam remains homogenous for at least 10 years, as experience has shown.

Dimensions of SEF® vessels

- Static SEF® vessels can be very large. The maximum quantity of stored foam is determined only by the mechanical manufacturing limitations.

Let the foam expand

- On release of the SEF® the pressurized foam will expand. This eliminates the need for aspirating devices.

- The release rate of the foam from the vessel is not bound by conventional limitations like aspirating devices and such equipment.

- The expansion ratio of the foam is independent from the flow rate, the pressure in the foam vessel is the only factor determining the expansion.

Operation of the system

- The operation of the whole system is extremely simple. All that is required is to open the isolation valve between the pressurized SEF® storage vessel and the foam application device.

- The simplicity eliminates the need for specialists to operate the system successfully.

Advantages of the SEF® system over a conventional system

- Requires no manpower resources to set up and operate at the scene of the fire.

- Is so simple that mistakes are unlikely.

- The foam is mixed under calm and controlled conditions, and is 100% consistent.

- Does not require any aspirating devices.

- Does have an unlimited flow range.

- Produces optimum quality foam at all flow rates.

- Has only a few critical elements requiring regular inspection.

- Requires considerably lower capital investment.

- Requires considerably lower maintenance effort and cost.

Applications where the SEF® concept can be used

- Hydrocarbon storage tank fire fighting by FoamFatale™

- New concept airport crash tenders

- First intervention vehicles

- Skid mounted units

- Fixed installations for restaurant cookers, fuel storage, underground fuel bunkers, portable and wheeled fire extinguishers

- SEF® tanks on vehicles, replacing or complementing conventional fire fighting vehicles

- Foam supply on sites handling flammable liquids that have no firewater system

- Foam supply for road car loading facilities handling flammable liquids

The FoamFatale™ storage tank fire protection system

- FoamFatale™ is a revolutionary new tank fire extinguishing technology using a very high foam application rate.

- The extremely high foam flow rate is provided through the new foam application device, which accommodates the very large foam flow and prevents excessive velocities in the nozzle. It is called Continuous Linear Nozzle (CLN). The CLN provides an ideal curtain-like foam application pattern, thus providing substantial and continuous cooling of the tank wall.

- One of the advantages of the Self-Expanding Foam concept is that it has no release rate limitations. By combining the SEF® method with the newly developed high capacity CLN, it is easy to achieve the application rates of 20-40 litres/minute/square meter.

- The result of this combination is an extremely efficient system. Tests were carried out on 500 m2 gasoline fires. The extinguishments were done in maximum 40 seconds. The reliability of the system is very high, the valve is the only moving part in it.

Advantages of the FoamFatale™ system over conventional systems

- Its reliability level is very high: the CLN can hardly be damaged by explosions or fire.

- It is sabotage-proof, the fire protection system of a tank farm -built by our method- has no common elements like a fire water system, which when destroyed would cause the malfunction of fire protection systems using firewater.

- Requires considerably lower capital investment.

- Requires considerably lower operating cost.

- The system is fully autonomous.

- Does not require firewater at all.

- It does not require external energy sources like fire truck or electric pump.

- It is so simple that mistakes under stressful fire conditions are unlikely.

- Automatic operation of the system further reduces air pollution caused by the fire.

- Its simplicity eliminates the need for specialists to operate and maintain the system.

- It uses perfectly proportioned foam, mixed under calm and controlled conditions.

- The foam is stored under pressure, no pump or other pressure-raising source is required.

- No aspirating device is required.

- Produces optimum quality foam at all flow rates.

- Its flow rate is virtually unlimited: pumps, proportioners, aspirating devices are not there.

- Very high foam-producing rates can be easily achieved at modest cost.

- Has only a few key elements requiring regular inspection.

- Is also suitable for the fire protection of rooms or large equipment and machinery.

Live fire test

A test tank was built in Hungary for demonstrations. The tank was used for experiments with flow rates and types of nozzles ultimately resulting in the current mature system.

Live tests on these 500 m2 gasoline fires repeatedly demonstrated that after maximum 40 seconds the fire went out so abruptly as if it had been cut off.

FoamFatale™ system is able to extinguish very large tank fires within maximum two minutes from the moment of ignition without intervention from any person.